September 27, 2024

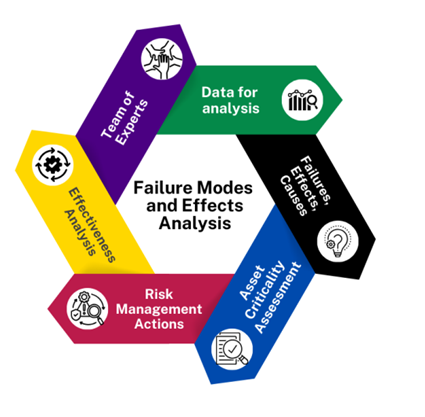

Failure modes and effects analysis (FMEA) is a systematic methodology used to evaluate component failure modes, including modes due to aging, and the overall affect those failure modes could have on the associated system. Figure 1 illustrates the process for conducting an FMEA.

No Department of Energy (DOE) regulation, directive, or standard requires contractors to perform FMEA on safety systems. Although not required, Washington River Protection Solutions, LLC (WRPS), an operating contractor at the Hanford Site, implemented a procedure in which its system engineers perform FMEA on safety and certain non-safety systems at the Tank Farms and 242-A Evaporator (Figure 2), depending on their graded importance.

Figure 1. Failure Modes and Effects Analysis Process Illustration

Figure 1. Failure Modes and Effects Analysis Process IllustrationWRPS systems engineers use FMEA to determine the tests and data collection needed to detect trends and non-optimal system performance prior to failure. They document this using a system performance monitoring plan. FMEA also forms the technical basis for determining preventive maintenance needed to increase reliability and extend system life. Finally, WRPS systems engineers use FMEA to develop a listing of critical spare parts for the system.

In summary, FMEAs provide a more in-depth understanding of system vulnerabilities that can be used as a basis for establishing more informed system monitoring, maintenance, and critical spares. WRPS has gone above DOE requirements in performing FMEAs on all safety and certain non-safety systems.

Figure 2. The 242-A Evaporator located at the Hanford Site’s 200 East Area is a facility operated by WRPS.

Figure 2. The 242-A Evaporator located at the Hanford Site’s 200 East Area is a facility operated by WRPS.